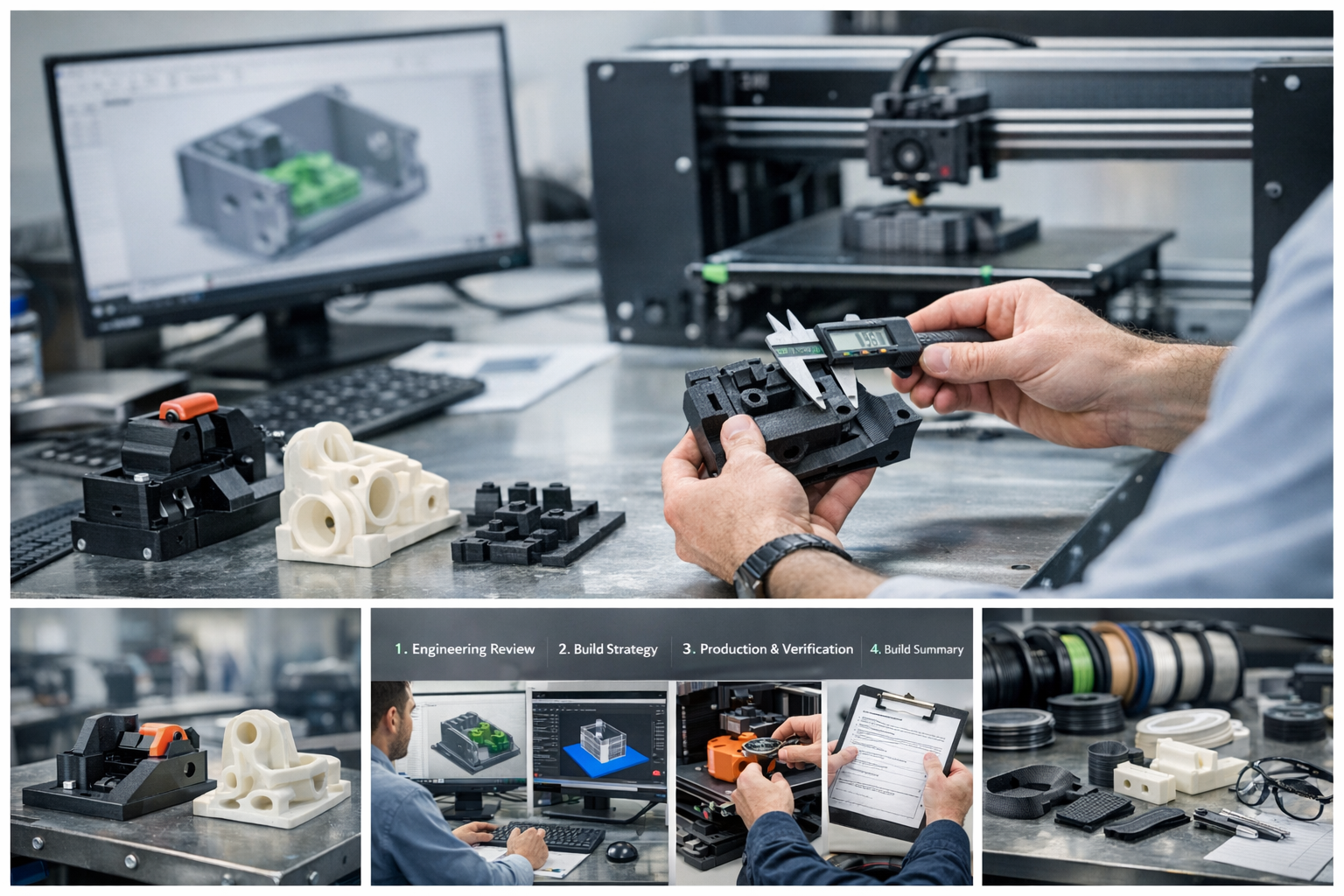

Engineering-led polymer additive manufacturing

KDP 3D Solutions delivers predictable prototypes, fixtures, and low-volume production parts reviewed by engineers for manufacturability, performance, and risk before they ever reach the printer.

What you get

No “upload and hope.” Every build is evaluated with engineering judgment so your parts fit, function, and ship on time.

Ideal for teams who care more about whether the part works than how fast it prints.

Accountability

We review manufacturability, risk, and performance before printing—so you avoid preventable reprints and delays.

Predictability

Documented workflows and revision control help you iterate faster and keep results consistent.

Communication

No ticket systems. No account layers. You get fast answers from someone who understands the part.

What we do best

We specialize in polymer additive manufacturing for functional applications, where fit, strength, and repeatability matter. We intentionally do not focus on decorative prints or hobby parts.

Performance-driven prototypes designed to validate fit, strength, and real-world use not just appearance.

Learn moreJigs, fixtures, assembly aids, and test adapters built for repeatability and shop-floor reliability.

Learn moreRevision-controlled parts for bridge production, pilot builds, and short-run manufacturing support.

Learn moreHow we work

We reduce risk by defining the build strategy intentionally and documenting what matters, so you can iterate confidently.

Orientation, tolerances, material suitability, and risk flags

Layer height, infill, supports, and post-processing plan

Controlled parameters with inspection for fit and finish

Per-order documentation to support traceability and repeatability

Materials

We support a focused set of proven materials for prototypes, tooling, and end-use parts. Material selection is guided by performance requirements, not convenience.

Form, fit, and fixtures where stiffness matters

Durable parts with improved chemical resistance

Better thermal stability and toughness

Strength-critical parts and tooling applications

Quality & confidence

Our workflows emphasize revision control, build traceability, controlled parameters, and consistent inspection standards,so you can buy parts with confidence.

Need documentation, confidentiality, and a predictable workflow? We’ll align with your requirements.

If you don’t have a Quality & Compliance page yet, create quality.php (I can generate it to match this style)

If you’re tired of surprises, reprints, and wasted iterations, let’s do it right the first time.